Customer Case

Iranian Bushehr Petrochemical Company is a very famous petrochemical company in Iran and the largest petrochemical company in Bushehr Province.Producing more than 5 million tons of sulfur, ethylene, polyethylene, methanol, acetic acid, ethylene glycol and ethylene each year, and undertaking many large-scale petrochemical projects,And has close ties with the Iranian National Petrochemical Company.The air separation project is located in Assaluye, Iran, and Hangzhou Hangyang Co., Ltd. is responsible for providing complete sets of equipment and implementation.

System Requirements

This project uses two 16000KVA transformers to convert two 20 KV incoming lines into 6.3KV and then supply power to the equipment. The system sets up a power distribution monitoring and control system PDCS to be responsible for monitoring and alarming the entire power system,And to achieve communication with the DCS system, load shedding, emergency diesel engine start and other functions.To this end, the system requires a set of RTU devices to implement the following functions:

-- Redundant configuration

It must have 2 independent processors (CPU redundancy), 2 independent memories, 2 independent power supplies and 2 sets of independent communication cards. 2 sets of RTUs work at the same time, and one set is used as another set of backups.

-- Load shedding control

The state information and the electric quantity information of each loop are collected, and according to the preset logic criterion, part of the load is gradually cut off according to the important level of the load when necessary to ensure the stable operation of the important load.

-- Upper and lower communication

Realize the communication collection of all field devices and forward them to the superior system according to the specified communication protocol. All the microcomputer protection devices and RTU communication requirements adopt the international standard IEC61850 communication protocol.

-- IO signal acquisition and control

RTU provides 400 points of switch input and 200 points of output, all upload IO information of SCADA system with time stamp function, all IO modules support hot swap and status indicator.

-- Logic programming function

Interlocking logic guarantees the correct start and stop of diesel.

System Configuration

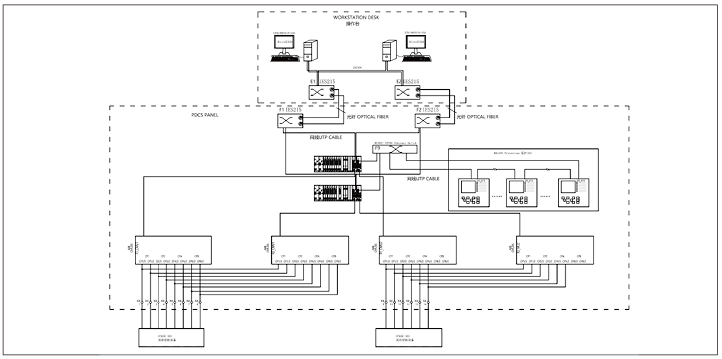

-- 2 sets of MicroSCADA system, the operation mode is hot standby

-- RTU screen side, including 2 sets of RTU560, redundant configuration

-- The main change protection screen side, the protection adopts RE_615 series

-- 25 sets of microcomputer protection devices, protected by RE_615 series

System Structure

-- System structure All protection provides 2 RJ45 Ethernet ports to communicate with 2 redundant RTU560s via Ethernet switch according to the old C61850 communication protocol.

-- All other smart devices provide one RS485 serial port to communicate with two redundant RTU560s in parallel according to the MODBUS communication protocol.

-- The RJ45 Ethernet ports of the two redundant RTU560s provide two independent Ethernet segments to the system layer through photoelectric conversion.

-- Two monitoring hosts are connected to two independent Ethernet segments to implement dual-network redundant communication and dual-system hot standby.